Polygeyser® Bead Filters are designed to operate as bio-clarifying filters providing both biological and mechanical filtration in a single, simple to operate unit. Mechanical filtration is accomplished as the water passes upwards through the matrix of bead media. Particles are strained from the water by the media bed. Both standard 1/8” round media and New Nitrotech™ Media have the ability to capture 100% of particles 50 microns and greater in size and 45% of particles between 5-49 microns in size per pass. Biological filtration is realized as nitrifying bacteria colonize the surface area of the media bed (400 ft2/ ft3). Each gentle air wash facilitates the removal of excess biofloc leaving a thin healthy film of nitrifiers for maximum biological filtration. Additionally, each backwash occurrence helps re-oxygenate the media bed, a key component in the nitrification process.

Nitrotech Media:

All Polygeyser® Bead Filters come standard with Nitrotech™ Media. This revolutionary, advanced biological media is the result of years of biological media research. This modified polyethylene bead media has proven to provide up to 100% higher nitrification rates over our standard 1/8” round polyethylene bead media while maintaining the same mechanical filtration performance. Nitrotech™ media provides a pocket (safe haven) for nitrifying bacteria to colonize. During the backwash process this pocket helps to protect the bacteria from dislodging from the media thus retaining a stronger bacterial colony for the biological process. Nitrotech™ media is an advanced proprietary biological media available only with Bead Filters.

Multigeyser™ Technology:

All Polygeyser® Bead Filters 12ft3 and larger employ our proprietary Multigeyser™ technology for higher efficiency backwashing. Multigeyser™ technology utilizes multiple triggers that fire their air charge simultaneously during a backwash. The firing of multiple air charges located strategically in the charge chamber allows for an even distribution of turbulence throughout the media bed thus causing greater agitation among the beads. The result is a comprehensive cleaning of the media bed over the larger surface area of our 12ft3 and larger models. Multigeyser™ Technology is only available on Polygeyser® Bead Filters.

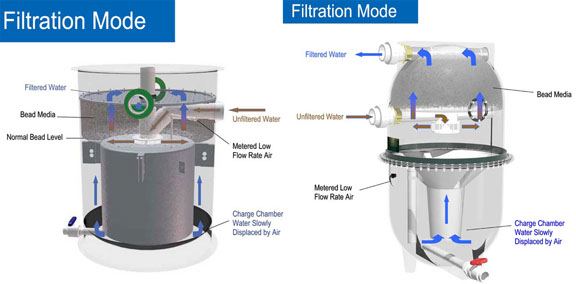

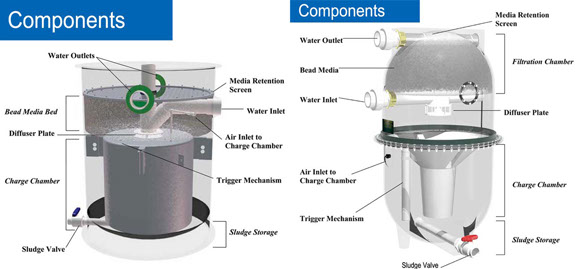

Polygeyser® Components:

The Polygeyser® Bead Filter is a floating media filter with 3 major chambers. The Filtration Chamber houses the bead media which captures solids and debris and provides surface area for biofiltration. The Charge Chamber is a dual purpose chamber firstly collecting air over time to release during backwash and secondly settling solids out of the backwash waters. And finally the Sludge Storage Chamber which concentrates and stores settled debris from the backwash process.

Click Pictures for larger image

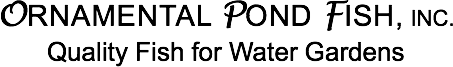

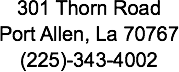

Polygeyser® Normal Operation:

During Normal Operation water from the pond/tank enters the inlet of the filter and is distributed evenly across the media bed via the diffuser plate. As solids laden water rises up through the bead media bed particles are strained out of the water by the bead matrix. Additionally, bacteria colonize the surface area of the beads (400 ft2/ ft3) biologically filtering the water via the nitrification process. Water then passes through the media retention screen and out of the outlet and back to the pond/tank. A small air pump is used to continually pump air into the air chamber at a very slow rate.

Click Pictures for larger image

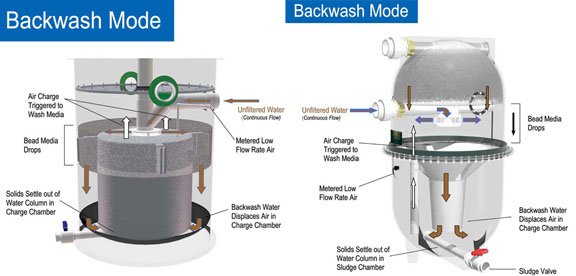

Polygeyser® Backwash Operation:

Once the air chamber has completely filled with air the trigger mechanism releases the air into the upper filtration chamber. As the air rises up through the bead bed the media is vigorously agitated dislodging the solid debris from the media bed. While the media bed is being agitated by air it is also dropping down causing further turbulence. All of the water from the filtration chamber flows down into the charge chamber. The mean while continuous water flow from the pond/tank is entering the filter. Upon completion of a backwash the charge chamber is full of backwash water and the media bed floats back up to continue filtering. Over the course of several hours the solids settle out of the water in the charge chamber into the sludge storage chamber. As air is slowly pumped into the filter the charge chamber water is displaced back into the filtration chamber at a velocity slow enough to prevent solids from rising up with the water. This process effectively concentrates the sludge in the bottom of the filter. The backwash frequency is determined by the flow rate of air into the charge chamber. The sludge storage chamber should be evacuated every few days to weeks depending on the system loading.

Click Pictures for larger image

Design and Photography credit, Wes Kennison, 2013